A level sensor is a device used to monitor, maintain, and measure the levels of liquid (and sometimes solid) substances. The sensor converts the perceived data into an electric signal once a liquid level is detected. Level sensors are primarily used in the manufacturing and automotive industries but can also be found in many household appliances, such as refrigerator ice makers. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

Distributing electronic tank level switches is the focus of our company. Let us solve your level gauging needs. We offer liquid level switches by Delavan, Omnitrol, Shand & Jurs and L&J Engineering. Some types include top mounted level switches, and liquid level switches offering alarm systems.

CME manufactures pressure switches, differential switches, level switches, vacuum switches, temperature switches and solid state pressure switches. CME serves a range of industries and markets with quality switches and related components. Call us today or visit our website for more information on our products and services.

AMOT USA remains a ground-breaker in temperature and pressure sensing and control. We have pioneered quality components, including level switches, for nearing 60 years. Try our electric level switch, stainless steel pneumatic level valve and other mechanisms for a total engine solution. Other products include a line of pressure switches.

More Level Sensor Manufacturers

A level sensor is capable of detecting and communicating a change to a user. Level sensors are typically designed for a single application rather than a broad range of applications.

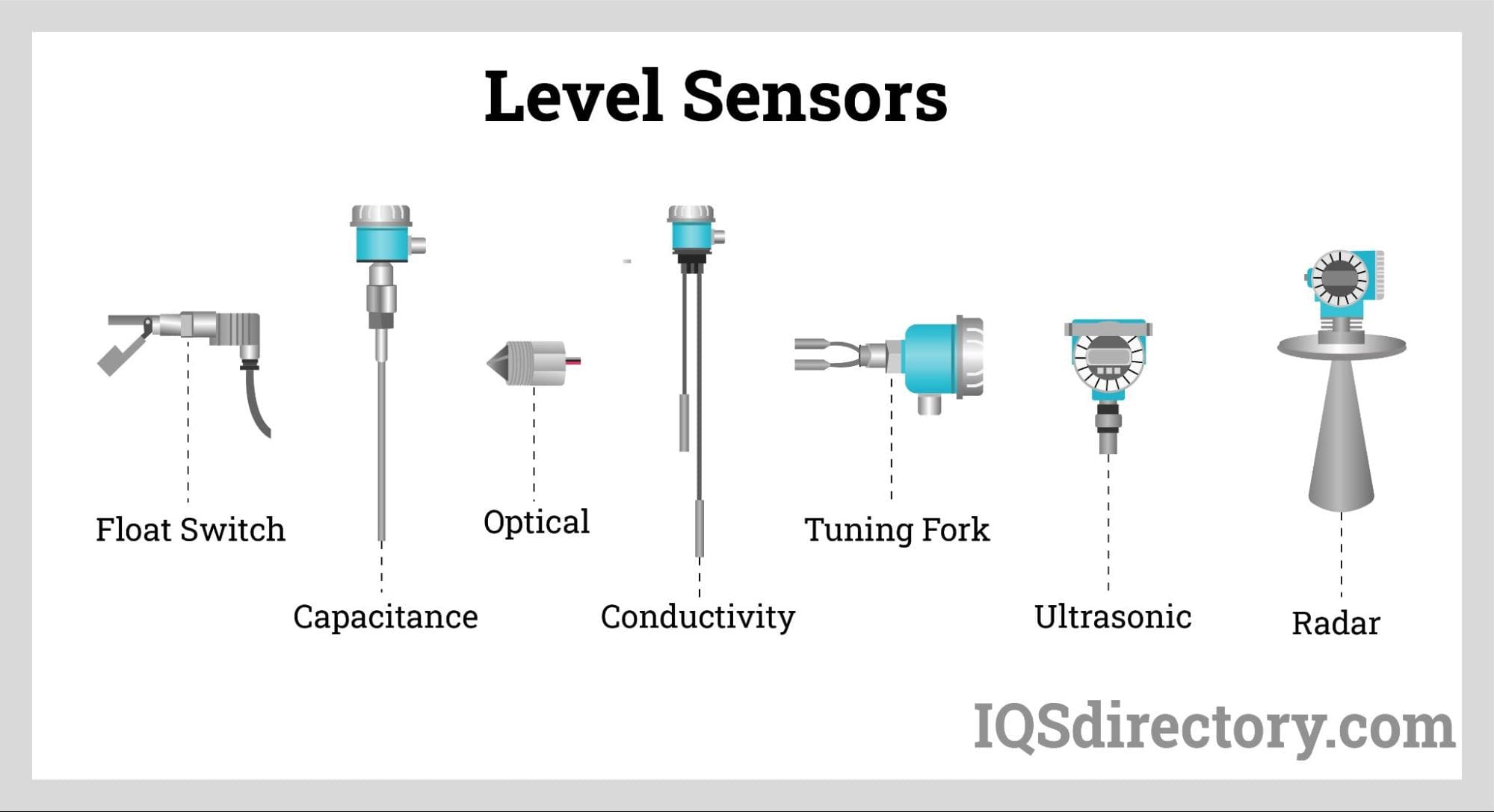

Types of Level Sensors

Level sensors can be split into two main categories.

Point Level Sensors:

Point level sensors mark a specific level and inform the user whether the media is above or below that level. In general, they are used as a high alarm or switch. These level sensors can also be combined in a single device to provide a low alarm or a stepped version of a continuous level. Examples of sensors for point-level indication include the following.

- Capacitance Level Sensors: A capacitance level sensor is a proximity sensor that emits an electrical field and detects a level based on the effect on its electrical field. These sensors are small, less costly than other sensors, less intrusive to the product, accurate, and do not have any moving parts. They must, however, be calibrated and will only detect specific liquids. Capacitance sensors can be used in liquid storage tanks.

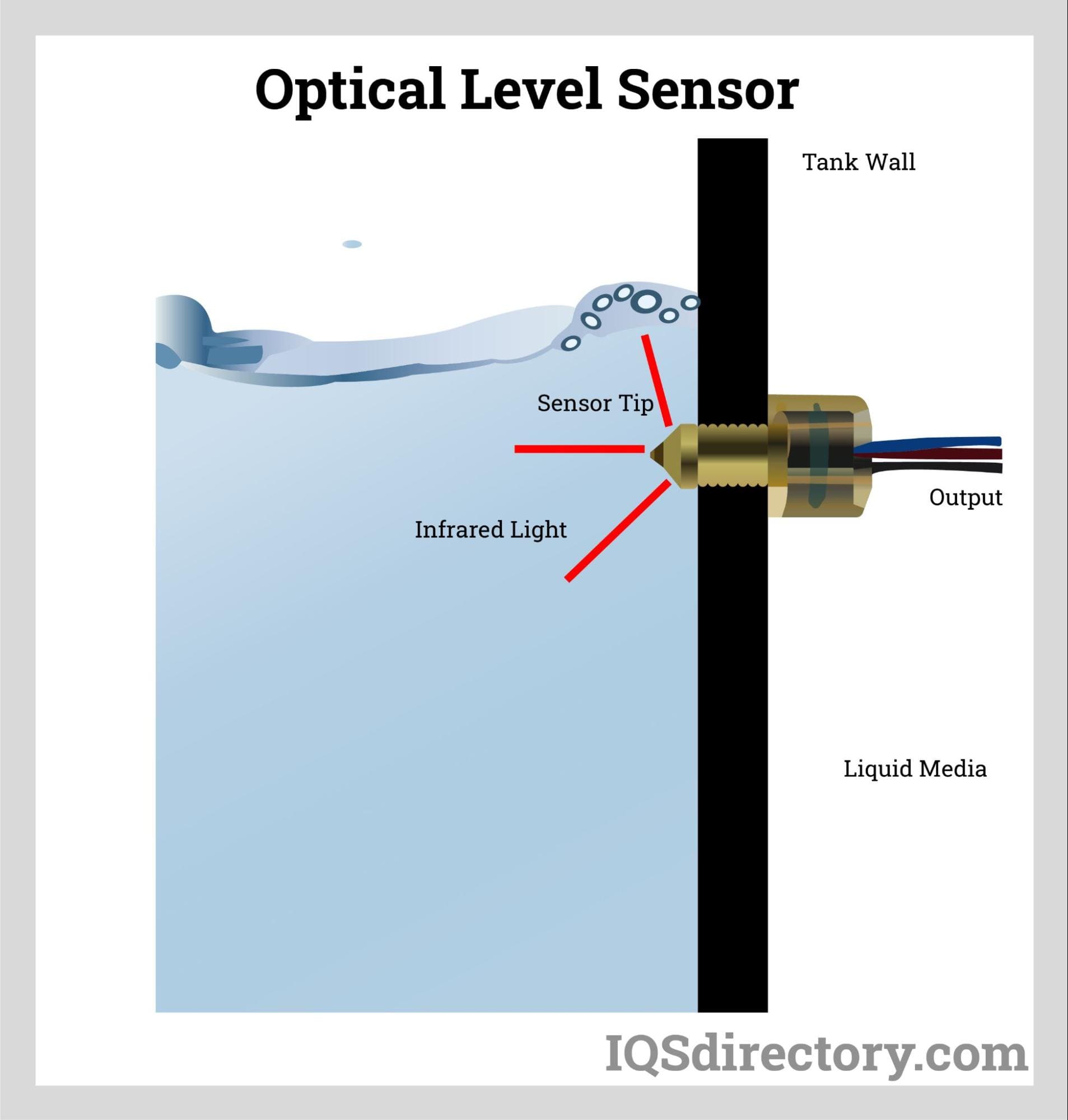

- Optical Sensors: Optical sensors convert light rays into electrical signals, translating the physical quantity of light into a measurement. These sensors contain no moving parts, are unaffected by high pressure or temperature, are compact, and can be used in liquid applications. However, they must be cleaned if their lens becomes coated or dirty. Oil, coolant, or hydraulics can be used as low-level indicators to prevent run-dry conditions.

- Conductivity (Resistance) Sensors: A conductivity or resistance sensor reads conductivity with a probe. The probe has two electrodes and uses alternating currents to power them. When a liquid covers the probe, the electrodes connect to an electric circuit, causing current to flow and signaling a high or low level. These conductivity level sensors have no moving parts, are inexpensive, and are simple to use. They are, however, invasive (they must touch the product being sensed), only detect conductive liquids, and the probe will rust over time. These sensors are useful for signaling high or low levels.

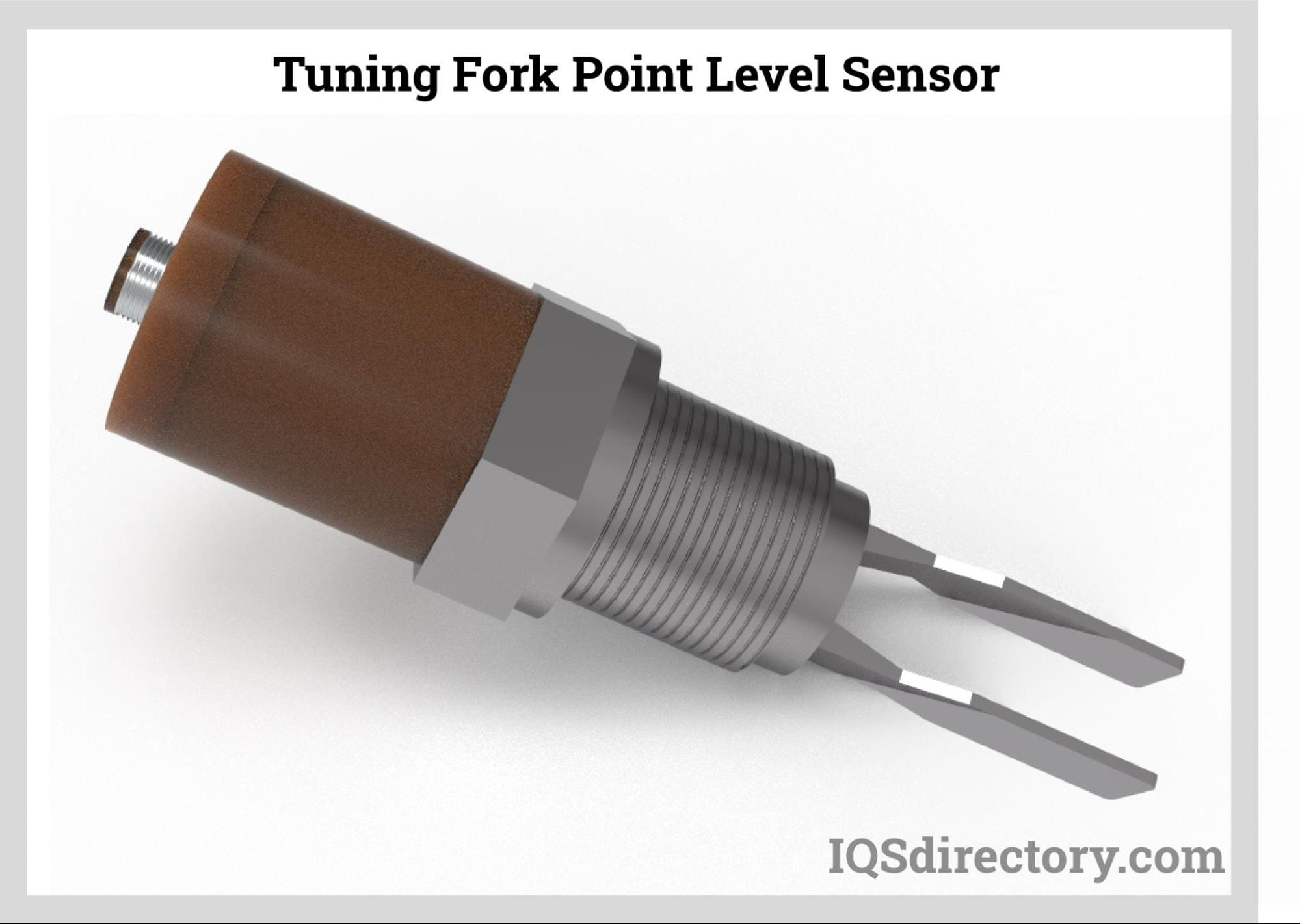

- Vibrating (Tuning Fork) Sensors: They employ a sensing element in the shape of a fork with two tines. The fork vibrates at the frequency of its natural resonant frequency. Therefore, the frequency of the fork detecting the level will change as the level changes. These sensors are inexpensive and small, invasive to the product, meaning they must touch the material to determine the level. They are simple to install and virtually maintenance-free. These sensors are used in the mining, food and beverage, and chemical processing industries.

- Float Switches: Float switches use a float, a device that raises or lowers when a product is applied or removed, opening or closing a circuit as the level rises or falls, moving the float. A float switch has many advantages. It does not require power, provides a direct indication, and is inexpensive. The disadvantages are that they are invasive to the product, have moving parts, and can be quite large. In addition, float switches can only indicate a high or low level and cannot measure a variable level. Float switches are commonly used in liquid storage tanks to indicate high or low levels.

Continuous Level Sensors:

They measure liquid or dry materials levels within a specified range and provide outputs that show the level continuously. They are more sophisticated than point-level sensors in that they measure over a range of levels rather than at a single point to provide the user with the exact amount of a substance. Continuous level measuring uses the following sensors.

- Ultrasonic-Level Sensors: Ultrasonic-level sensors generate and receive ultrasonic waves using the time it takes to reflect and measure distance. Ultrasonic sensors have no moving parts, are compact, extremely reliable, non-invasive (non-contact), unaffected by the properties of the material they are sensing, and self-cleaning due to vibrations produced. They are, however, costly and may be affected by the environment.

- Radar (Microwave) Sensors: These sensors use an antenna on the radar sensor to transmit microwaves. The product being sensed reflects these microwaves to the antenna, and the time between signal emission and reception is proportional to the product level. Radar sensors offer many benefits. They are not affected by temperature, pressure, or dust and can measure liquids, pastes, powders, and solids. They are also very accurate and do not require calibration, and they are non-invasive because they do not have to touch the product. They are, however, expensive and have a limited detection range. Radar sensors, like ultrasonic sensors, are ideal for hot liquid storage tanks.

Applications of Level Sensors

Level sensors are used in the following applications:

- automobiles in fuel tanks

- pharmaceutical processes

- power generation plants

- water treatment

Advantages of Level Sensors

- They give accurate values.

- They are robust.

- They have different configurations for different applications.

Disadvantages of Level Sensors

- They are only used in specific liquids.

- Digital-level sensors are complex.

Choosing the Proper Level Sensor Manufacturer

To ensure you have the most beneficial outcome when purchasing level sensors from a level sensor manufacturer, it is important to compare several companies using our directory of level sensor manufacturers. Each level sensor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each level sensor business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple level sensor companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services