Level indicators are mechanisms used to measure fluid levels in numerous industrial applications. They accurately determine the liquid levels in a tank, drum, or other containers. There are several kinds of indicators used in commercial industries. Read More…

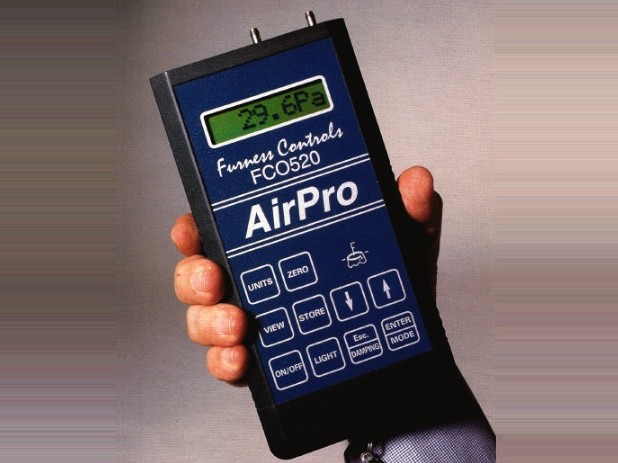

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Level Indicator Manufacturers

Level Indicator Machines: Comprehensive Guide to Types, Working Principles, Applications, and Supplier Selection

What is a Level Indicator Machine?

A level indicator machine—also known as a liquid level indicator or tank level sensor—is an essential industrial instrument used for measuring, monitoring, and controlling the levels of liquids or solids within tanks, vessels, and containers. These devices provide visual or electronic feedback about the height or volume of a substance, ensuring optimal process control and safety in a wide range of applications. Whether used for water tanks, chemical processing, oil and gas storage, or industrial manufacturing, level indicators help to prevent overflow, dry running of pumps, and other costly operational issues.

Level indicators are available in various designs to suit different process requirements, including float level indicators, magnetic level indicators, ultrasonic level sensors, and capacitive level indicators. Their selection depends on the application, medium properties, measurement accuracy, and environmental considerations.

How Does a Level Indicator Machine Work?

Level indicators operate by using sensor probes or float mechanisms to detect the level of a liquid or solid inside a storage container, tank, or vessel. These sensors transmit electrical or mechanical signals to a control panel, which then triggers an alarm, LED indicator, or other visual/audible signal to alert the operator. In advanced systems, the panel can be configured to automatically turn pumps on or off depending on whether the tank is empty or full, supporting automated process control and energy efficiency.

The specific working principle of a level indicator varies based on the technology used. Common methods include mechanical floats, magnetic coupling, optical sensors, ultrasonic waves, and capacitive or conductive probes. Depending on the application, the level indicator machine may provide continuous level monitoring or point level detection.

Types of Level Indicators

Selecting the right level indicator technology is critical for optimal performance, safety, and cost-effectiveness. The main types of level indicators include:

1. Transparent Level Indicator

Transparent level indicators use two parallel plates of toughened transparent glass to display the liquid level. Fluid inside the chamber is visible through the glass, and the interface between the liquid and vapor phases is easily discernible due to differences in transparency. These indicators are ideal for applications where direct visual observation is preferred, such as boiler drums and chemical tanks.

- Robust construction for high-pressure and high-temperature applications

- Suitable for corrosive and hazardous fluids when fitted with special glass and gaskets

- Enable visual monitoring for quick inspection and process validation

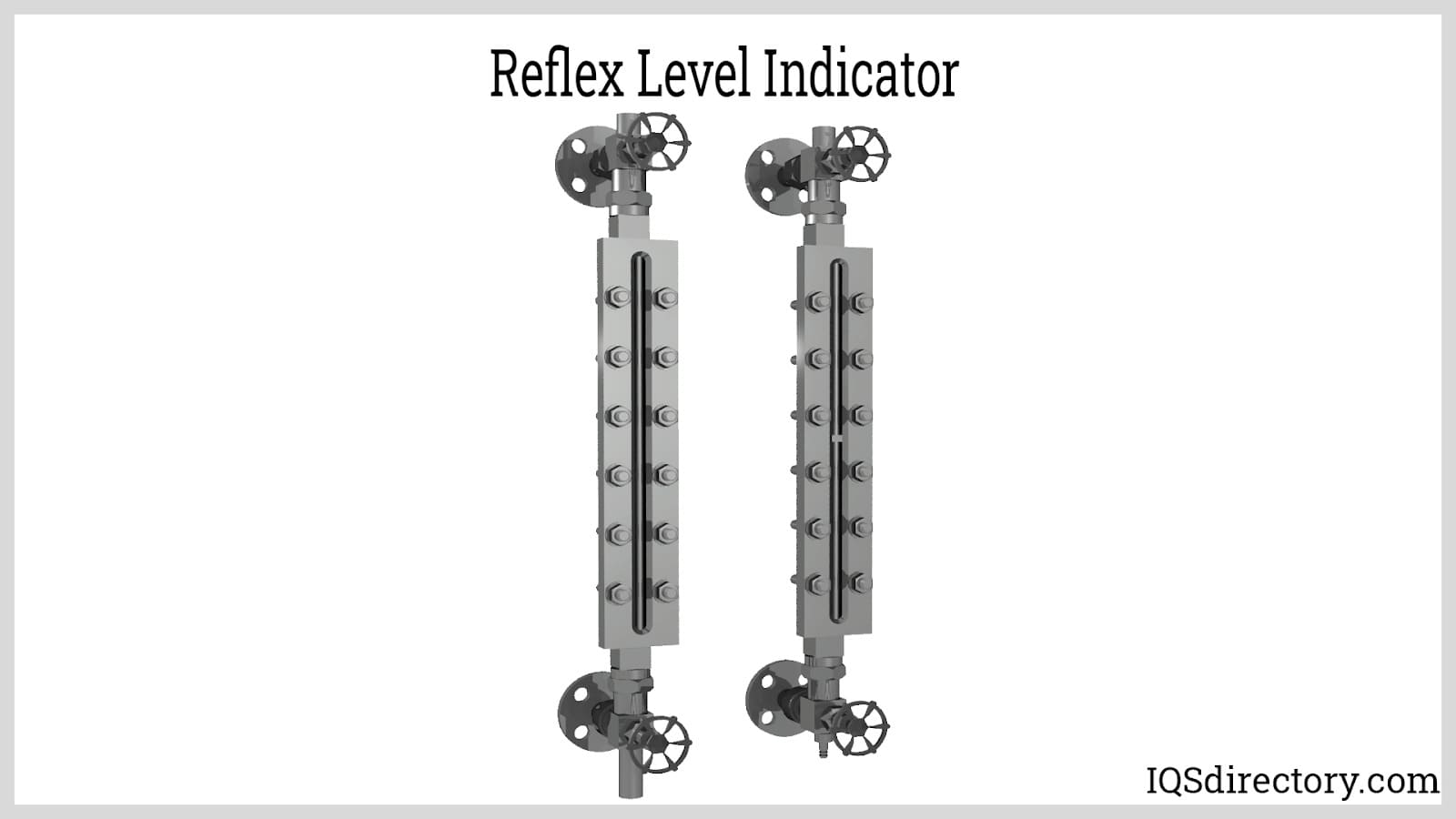

2. Reflex Level Indicator

The reflex level indicator leverages the physical principles of reflection and refraction. Its glass face features prismatic grooves on the side facing the liquid chamber. When the chamber contains a liquid, light is absorbed and appears dark; when filled with vapor or gas, the grooves reflect light, appearing bright. This contrast clearly marks the liquid level, making it easy to read even in challenging conditions.

- Excellent visibility in both day and night, especially with artificial lighting

- Widely used for water, oil, and steam level measurement

- Low maintenance and reliable in harsh process environments

3. Magnetic Level Indicator

Magnetic level indicators offer a non-invasive, leak-proof solution for continuous liquid level measurement. They utilize a float containing a magnet that moves up and down with the liquid level inside an external chamber. As the float moves, it magnetically actuates a series of flaps or indicators on the outside of the chamber to provide a clear visual display. These devices are prized for their safety in chemical, petrochemical, and pharmaceutical industries, where hazardous or aggressive fluids require hermetically sealed systems.

- No direct contact between indicator and process liquid, minimizing risk of leakage or contamination

- Can be equipped with level switches, remote transmitters, and alarms for comprehensive process integration

- Suitable for high-temperature and high-pressure applications

4. Additional Level Indicator Technologies

In addition to the types described above, there are several other level indicator technologies available to meet unique process requirements:

- Float Level Indicator: Uses mechanical floats to detect liquid levels. Common in water tanks, sumps, and reservoirs.

- Ultrasonic Level Indicator: Employs ultrasonic waves to measure distance to the liquid surface, providing non-contact level measurement. Used in open tanks, hazardous, or corrosive environments.

- Capacitive Level Indicator: Measures changes in capacitance as the level of conductive or dielectric material changes. Widely used in food processing, pharmaceutical, and chemical industries.

- Radar Level Indicator: Utilizes microwave radar signals for continuous, highly accurate level measurement in tanks with vapors, dust, or turbulence.

- Conductive Level Indicator: Relies on the electrical conductivity of the liquid to complete a circuit and indicate level. Often used for water, acids, and caustic solutions.

- Hydrostatic Level Indicator: Calculates level based on the pressure exerted by the liquid column. Common in deep wells, boreholes, and municipal water systems.

Key Applications of Level Indicators

Level indicators serve a vital role in industries and facilities where monitoring liquid or solid levels is essential for safe and efficient operation. Common level indicator applications include:

- Industrial tanks: Gauging the levels in storage drums or tanks containing oil, water, chemicals, or fuels.

- Pumping systems: Automated control of sewage pumps, sump pumps, and booster pumps to prevent overflow or dry running.

- Cooling towers: Monitoring tower cooling water levels to maintain optimal heat exchange efficiency.

- Steam boilers: Ensuring safe steam level monitoring in power plants and process industries.

- Environmental monitoring: Early warning systems for tsunamis, flood control, and sea level rise detection.

- Batch processing: Accurate batch processing and monitoring in food, beverage, and chemical industries.

- Agricultural irrigation: Precision control of water levels in canals, ponds, and reservoirs to maximize crop yield.

- Pharmaceutical manufacturing: Maintaining precise fluid levels for quality control and regulatory compliance.

- Marine and shipping: Ballast tank level monitoring and fuel management for vessels and offshore platforms.

- Mining and minerals: Level measurement in slurry tanks and leaching processes for efficient material handling.

Benefits and Advantages of Using Level Indicators

Investing in a modern level indicator system offers a range of benefits that improve operational safety, efficiency, and cost savings. Below are some of the top advantages of level indicators:

- Power Saver: Many automatic level indicators require minimal energy to function, helping reduce operational costs and support sustainability initiatives.

- Cost-Effective: Level indicators are relatively inexpensive to manufacture and install, offering a high return on investment for industrial automation and process control.

- Automation and Remote Monitoring: Advanced electronic and digital level indicators can be integrated with SCADA systems, PLCs, or remote data loggers for centralized control and reduced manual intervention.

- Accurate and Reliable: High-precision sensors and robust construction ensure consistent, repeatable level measurement over long periods.

- Customizable Solutions: Wide variety of technologies and materials available to suit specific process fluids, temperature ranges, and pressure requirements.

- Enhanced Safety: Prevents dangerous overflows, dry-running pumps, and environmental incidents by providing real-time alerts and automatic shut-off functionality.

- Low Maintenance: Many level indicators are designed for long service life with minimal maintenance, especially non-contact and sealed systems.

- Regulatory Compliance: Facilitates compliance with industry standards and safety regulations in critical sectors such as pharmaceuticals, food & beverage, and petrochemicals.

Limitations and Drawbacks of Level Indicators

While level indicator devices are highly beneficial, it’s important for buyers and engineers to be aware of common limitations:

- Component Wear: Water level controls and sensor probes may require replacement after extended exposure to humid or corrosive environments.

- Corrosion and Deterioration: Metallic components may suffer rust or degradation if not properly protected, especially with aggressive chemicals or saltwater.

- Electronic Vulnerability: Electronics in level indicators often require additional enclosure or sealing to prevent moisture ingress and damage.

- Complex Installation: Some level indicator systems, particularly those for hazardous or pressurized applications, require skilled technicians for setup and calibration.

- Medium Compatibility: Not all level indicator types are suitable for every fluid (e.g., viscous, abrasive, or foaming liquids may affect measurement accuracy).

- Limitations in Non-Standard Tanks: Irregularly shaped tanks or those with internal obstructions can pose challenges for certain sensor technologies.

How to Select the Right Level Indicator for Your Application

Choosing the ideal level indicator solution for your needs involves careful consideration of several key factors. If you’re exploring which level indicator is best for your tank or process, start by evaluating the following criteria:

- Medium type: Is the process fluid water, oil, chemicals, slurry, or a bulk solid? Consider fluid properties such as conductivity, corrosiveness, and viscosity.

- Tank size and geometry: What are the dimensions, shape, and mounting options for your tank or vessel?

- Measurement range and accuracy: Do you need point-level detection or continuous level monitoring? What level measurement accuracy is required?

- Process conditions: Account for temperature, pressure, and potential presence of vapors, foam, or turbulence.

- Safety and regulatory requirements: Ensure compliance with relevant safety standards and industry regulations.

- Integration needs: Will the level indicator be connected to a PLC, DCS, SCADA system, or require remote monitoring?

- Maintenance and lifecycle costs: Evaluate maintenance requirements, ease of calibration, and total cost of ownership.

- Supplier support: Does the supplier offer technical support, training, and spare parts availability?

Search-Driven Prompts: Questions to Ask When Evaluating Level Indicator Solutions

- What type of level indicator is best suited for hazardous chemicals?

- How accurate are ultrasonic versus magnetic level indicators?

- What are the maintenance requirements for float-type level indicators?

- Can level indicators be integrated with existing industrial automation systems?

- Which level indicator technologies are recommended for high-pressure or high-temperature environments?

- What is the typical lifespan of a level indicator device?

- How do I choose between continuous and point level measurement?

- Are there explosion-proof or intrinsically safe level indicators for hazardous areas?

Choosing the Correct Level Indicator Supplier

To ensure you have the most productive outcome when purchasing level indicators from a reputable level indicator supplier, it is important to compare several providers using our comprehensive directory of level indicator manufacturers and distributors. Each supplier profile highlights their areas of experience, certifications, and product capabilities, with direct contact options for information or requesting a quote.

- Compare technical specifications, certifications, and industry experience across multiple suppliers.

- Review each level indicator company’s website using our patented website previewer for quick evaluation.

- Request references, datasheets, and application case studies to validate supplier expertise.

- Use our streamlined RFQ form to contact multiple suppliers and receive competitive quotes.

- Assess after-sales support, warranty terms, and availability of spare parts and accessories.

- Consider choosing a supplier that offers field installation, commissioning, and training services.

Tip: When comparing level indicator suppliers, prioritize those with proven track records in your industry, strong customer support, and the ability to customize solutions to your process requirements.

Frequently Asked Questions (FAQs) About Level Indicators

- What is the difference between a level indicator and a level switch? Level indicators provide continuous or visual level measurement, while level switches are point-level devices that trigger alarms or controls at preset levels.

- Are level indicators suitable for both liquids and solids? Yes, certain types (such as radar, ultrasonic, and capacitance) can measure levels of powders, granules, and other bulk solids in addition to liquids.

- How often should level indicators be calibrated? Calibration frequency depends on application, process conditions, and manufacturer recommendations, but annual or semi-annual checks are common for critical processes.

- Can level indicators be retrofitted to existing tanks? Many level indicator types can be retrofitted; consult your supplier for compatibility with your tank design and process requirements.

- What is the typical lead time for level indicator delivery? Standard models may be shipped in days; custom-engineered solutions or specialized certifications can require several weeks.

Ready to Source the Right Level Indicator Machine?

Whether you’re seeking to upgrade existing equipment, automate your process, or meet regulatory demands, finding the right level indicator machine is crucial. Explore our directory of trusted level indicator suppliers to compare solutions tailored to your industry and application. Request a quote or contact our experts for personalized recommendations, technical support, and pricing information.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services