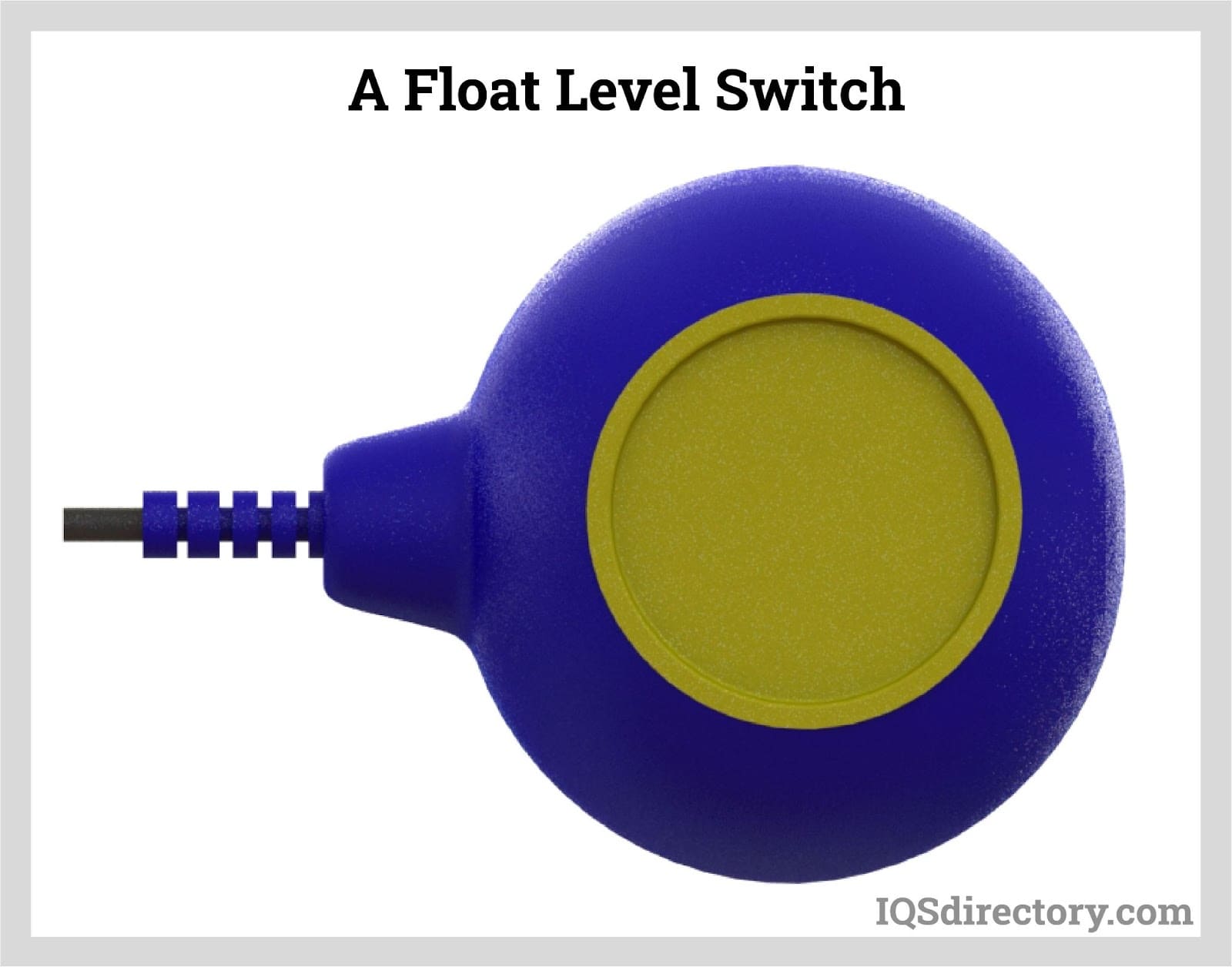

Float-level switches are utilities used to control and monitor the liquid level in transmission and storage facilities or systems. The correct measurement of liquid levels is very important in a transmission apparatus or a storage enclosure. In fuel-storage tanks, for example, there is no way to determine the fuel level except through float-level switches. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

Distributing electronic tank level switches is the focus of our company. Let us solve your level gauging needs. We offer liquid level switches by Delavan, Omnitrol, Shand & Jurs and L&J Engineering. Some types include top mounted level switches, and liquid level switches offering alarm systems.

CME manufactures pressure switches, differential switches, level switches, vacuum switches, temperature switches and solid state pressure switches. CME serves a range of industries and markets with quality switches and related components. Call us today or visit our website for more information on our products and services.

AMOT USA remains a ground-breaker in temperature and pressure sensing and control. We have pioneered quality components, including level switches, for nearing 60 years. Try our electric level switch, stainless steel pneumatic level valve and other mechanisms for a total engine solution. Other products include a line of pressure switches.

More Float Level Switch Manufacturers

Float-level switches are usually used to control other devices like pumps and alarms when a liquid has risen or fallen to a specific point. These switches are sought after because they are reliable, cost-effective, and can be used in different liquids.

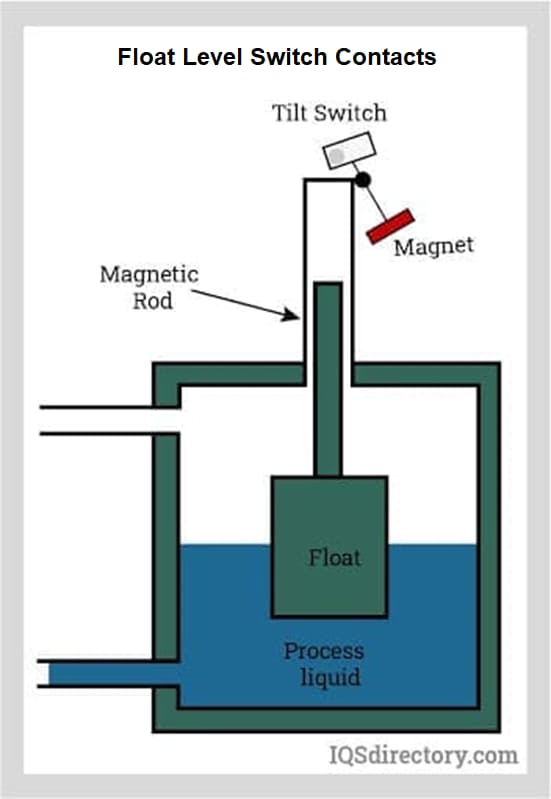

Components of Float Level Switches

Sensor Component – The sensor is the main component of a float-level switch. These sensors activate as fluids fall out of predetermined levels.

Output Signal – As the float level switch’s sensors activate due to changes in fluid level, they provide various output signals which help provide important data to the computer system they are connected to.

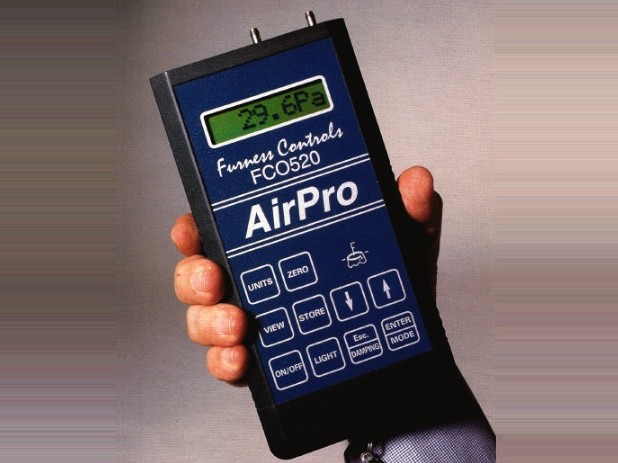

Interface – There are different types of displays for float-level switches. Analog displays consist of a button, dial, or needle to set the switch parameters. Digital ones have numeric readings, and they are more user-friendly. Some computer systems may have multiple float-level switches connected to them for monitoring various and interconnected readings. The computer may also be set up to properly arrange input data and give an output display as a video.

How Float Level Switches Function

A float-level switch consists of a hollow body with a sensor or a switch that is usually a reed switch. This electromechanical switch sends signals via an electromagnetic coil. The switch will have a magnet inside. Due to the level of the media within and the force of gravity, the switch closes or opens. The main function of float level switches is to trigger an alarm when the liquid level is outside the standard. The float level switch sends a signal that opens or closes a connected device.

Types of Float Level Switches

The different types of float-level switches include:

Stem-Mounted Float Switches

Stem-mounted float-level switches can be complex or very simple. They can be as simple as point switches consisting of one float on a single stem. Stem-mounted float switches can also have multi-point switches consisting of several floats on one stem. They can be present in horizontal and vertical orientations. They constrain the motion of the float.

Cable-Suspended Float Switches

As the name suggests, these float switches are suspended to a cable above the determined fluid level. Their sensors are then activated as liquid levels change, and their (floating) position with the cable and the liquid level is altered- for example, the switch will become more horizontal as it begins to float through an increased liquid level. They can be simple and have a single point that controls a switch, or they can be complex with many switch points. If the cable-suspended switch is not tethered, it will simply comply with the liquid level.

Applications of Float Level Switches

Float-level switches have several uses and applications across various industries. Some of their uses are seen in the following industries

- Aerospace

- Automotive

- Manufacturing

- Mining

- Medical

Benefits of Float Level Switches

Float-level switches are packed with numerous economic advantages for controlling, monitoring, and regulating liquids.

Waste Prevention – Controlling bulk liquid material helps in avoiding waste from overflows and spillages. The correct amount of liquid or fluids is maintained constantly with continuous level measurement.

Money Savings – The use of float-level switches has greatly helped to save money in various industries. Float-level switches can provide detailed data on the quantities and volume of the materials in question.

Reliability - The design of float-level switches caters for great performance and accuracy of data.

Switch Installation – The installation of these switches is very easy. This is an advantage if changes are made in storage arrangements and their location needs to be altered as a result.

Compact Benefit – They have a compact design. This makes them easy to fit into any container despite its size, location, dimensions, or shape.

Switch Sensitivity – Float-level switches have a high level of sensitivity, and they provide very precise data

Choosing the Right Float Level Switch Supplier

To ensure you have the most positive outcome when purchasing float level switches from a float level switch supplier, it is important to compare several companies using our directory of float level switch suppliers. Each float level switch supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each float level switch business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple float level switch companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services