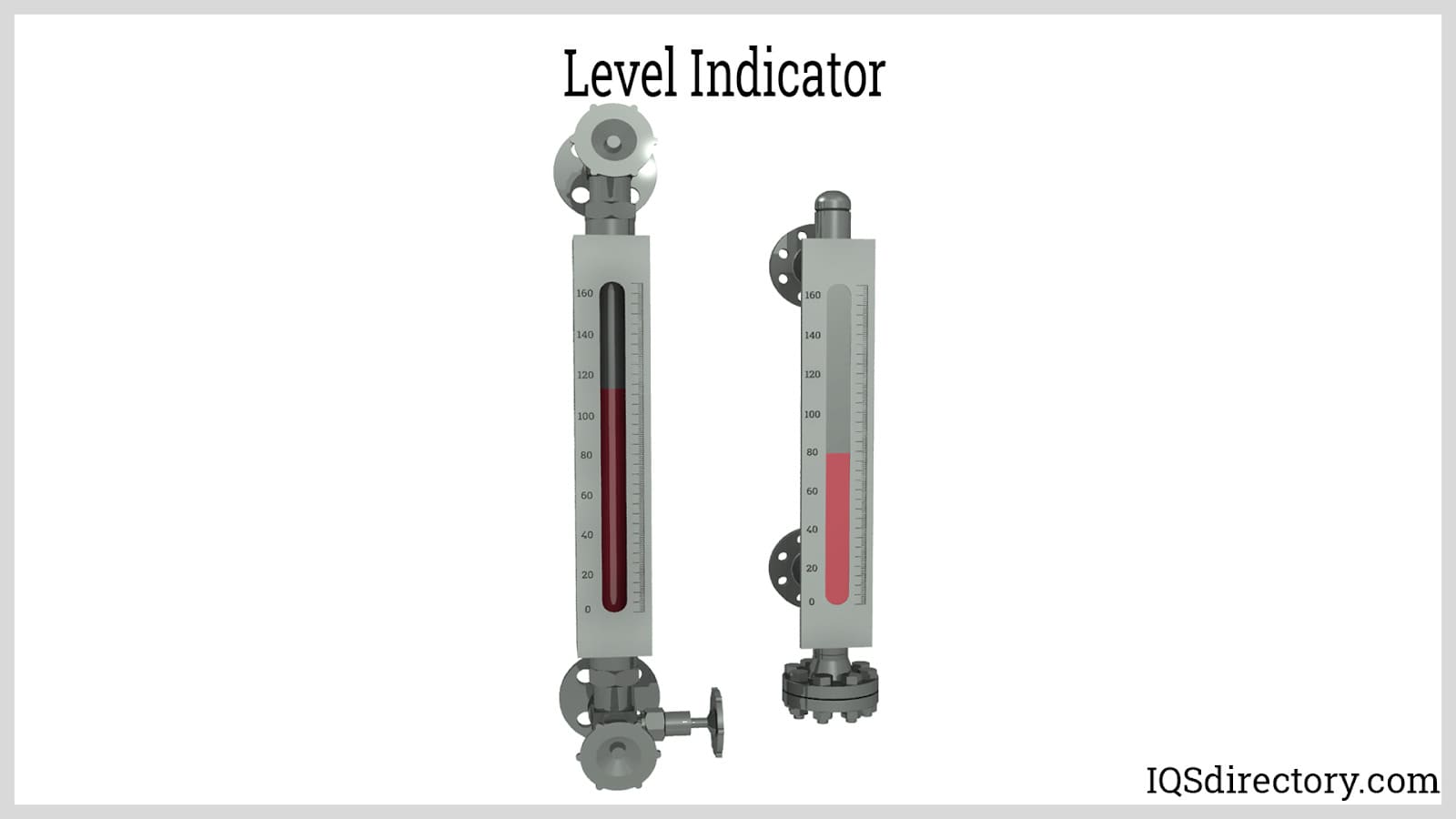

Level indicators are mechanisms used to measure fluid levels in numerous industrial applications. They accurately determine the liquid levels in a tank, drum, or other containers. There are several kinds of indicators used in commercial industries. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

Distributing electronic tank level switches is the focus of our company. Let us solve your level gauging needs. We offer liquid level switches by Delavan, Omnitrol, Shand & Jurs and L&J Engineering. Some types include top mounted level switches, and liquid level switches offering alarm systems.

CME manufactures pressure switches, differential switches, level switches, vacuum switches, temperature switches and solid state pressure switches. CME serves a range of industries and markets with quality switches and related components. Call us today or visit our website for more information on our products and services.

AMOT USA remains a ground-breaker in temperature and pressure sensing and control. We have pioneered quality components, including level switches, for nearing 60 years. Try our electric level switch, stainless steel pneumatic level valve and other mechanisms for a total engine solution. Other products include a line of pressure switches.

More Level Indicator Manufacturers

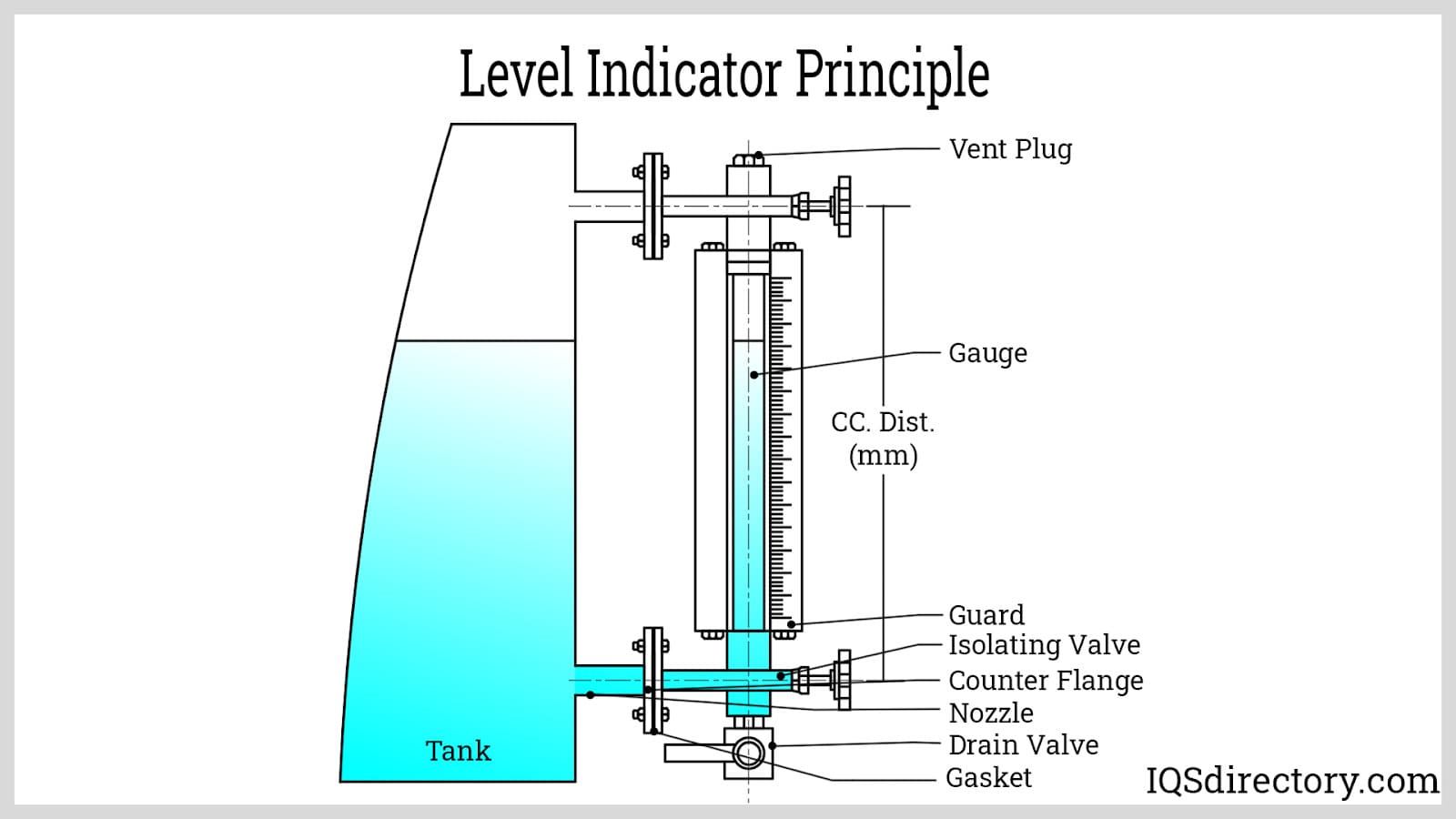

How Level Indicator Machine Works

Level indicators operate by using sensor probes to indicate the level of water inside a storage container. The probes transmit signals to a control panel that triggers an alarm or indicator. The panel can be set to automatically turn the pump on or off depending on whether the tank is empty or full.

Types of Level Indicators

The different types of level indicators include:

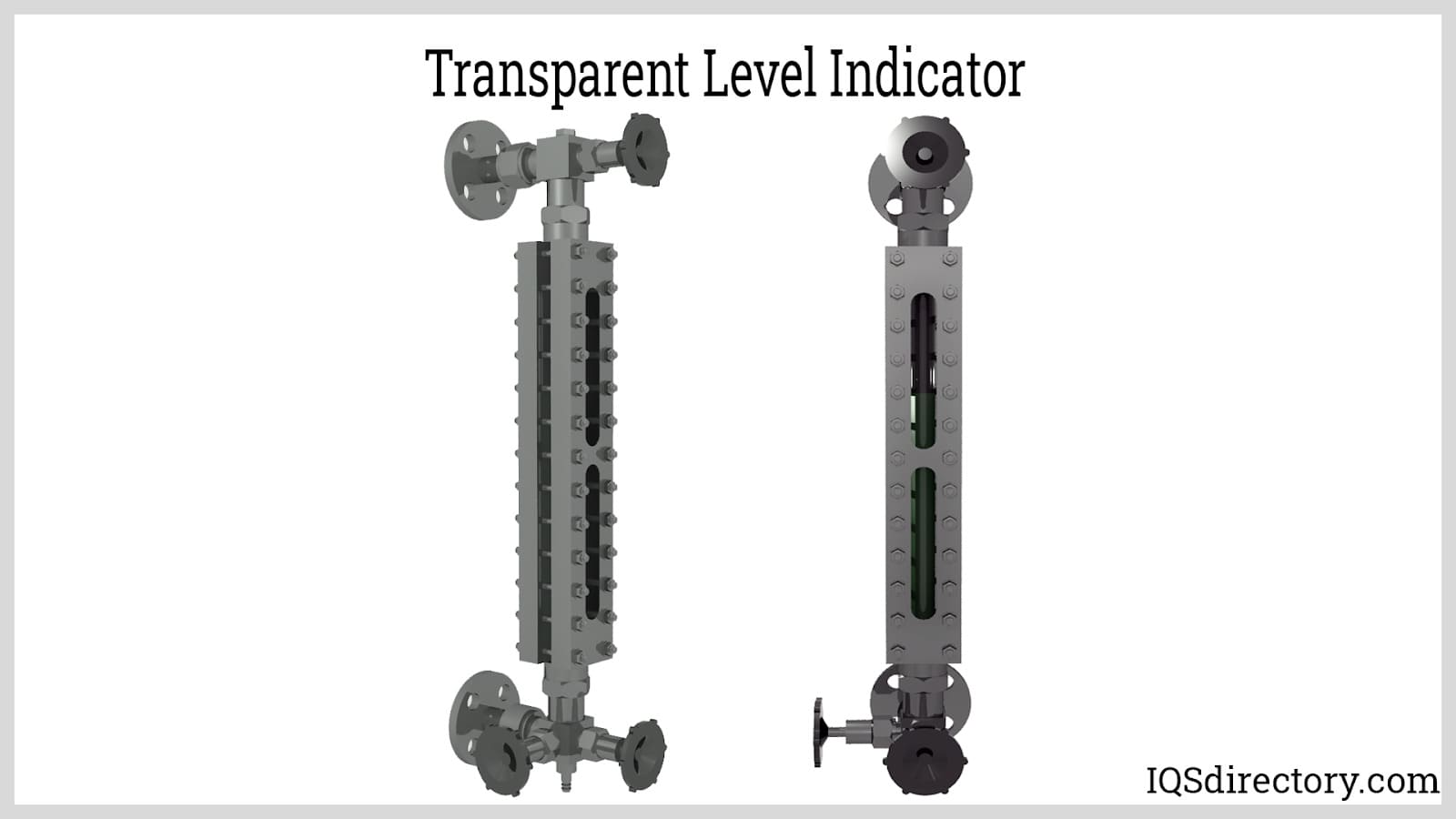

Transparent Level Indicator

Unlike glass tube gauges, transparent gauges are fitted with two plate transparent glasses which contain the fluid. The level of the fluid is indicated by transparency differences between the two media. A water stream is indicated by upward motion towards the surface of separation. For gaseous substances, light at the back of the gauge will reflect rays at the observer. This device has a metal body designed with an inside chamber and one or more windows. Each window has a special resistant transparent glass lined with a sealed joint and a metallic plate secured by joints and nuts. The chamber is coupled with a vessel threaded and welded on both ends.

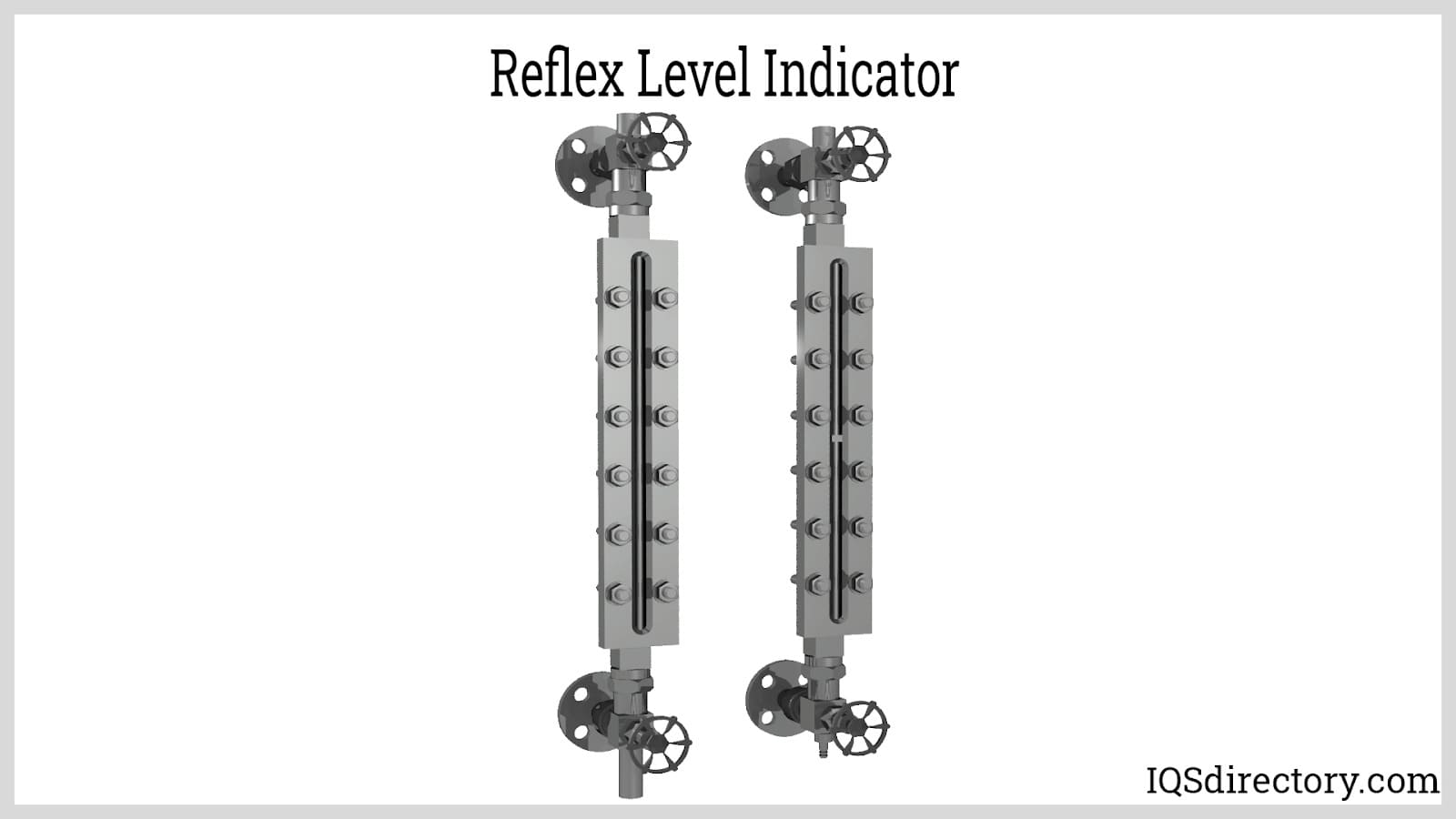

Reflex Level Indicator

The reflex level indicator uses laws of reflection and refraction. The face of the glass has prismatic grooves facing inwards towards the chamber. During use, the chamber is filled with fluid in the lower zone, and gasses are put in the upper zone. The level of the liquid is distinguished by the difference in brightness of the glass. During the nighttime, an artificial light source can be used to see the variations.

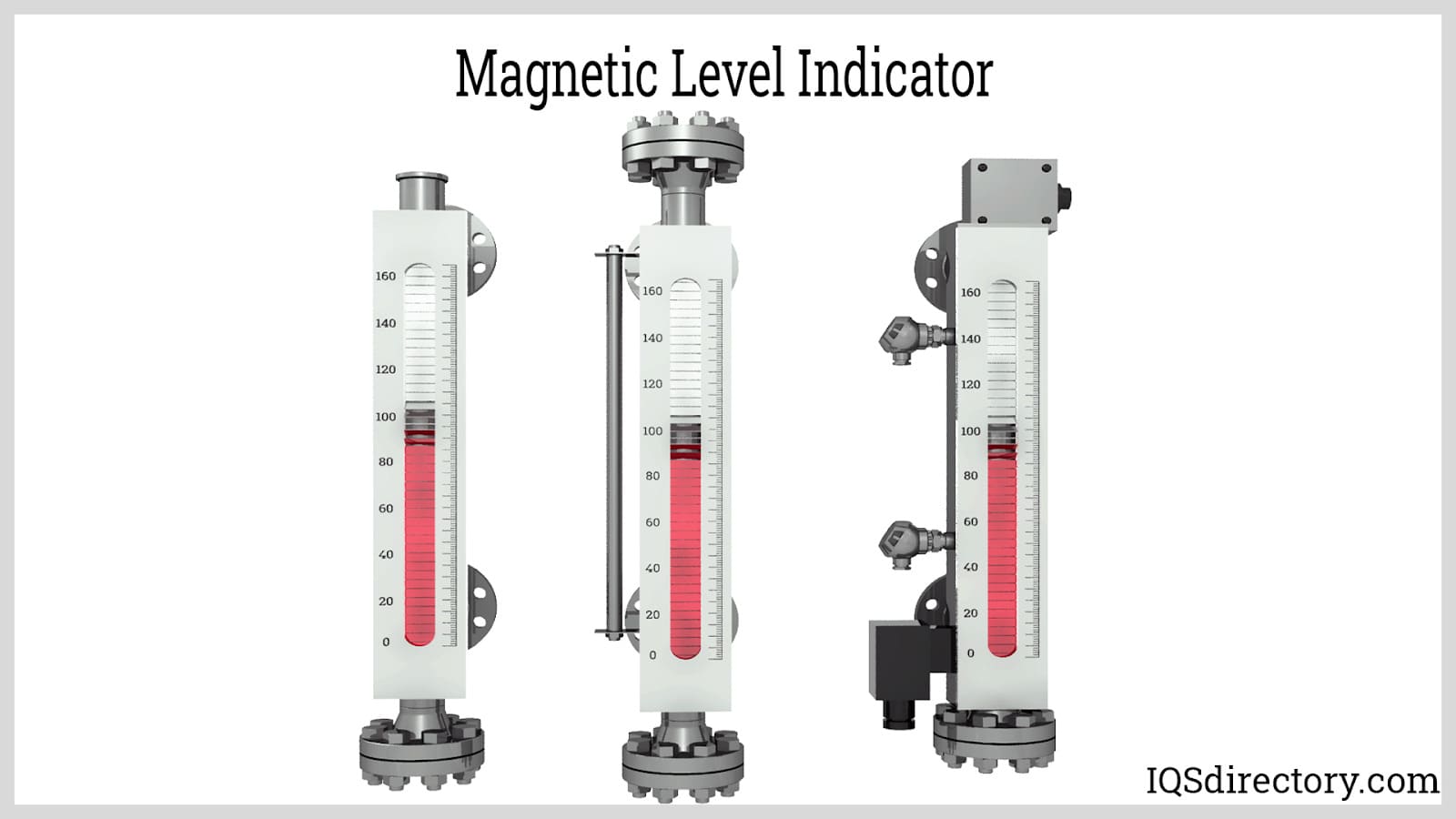

Magnetic Level Indicator

The magnetic level indicator can read the level indication in any plant or operating condition. It also provides preventative protection from leakages when dealing with chemically aggressive fluids. Each cylinder will display half of its surface externally and the indicated scale will be of one color (usually white), and a red color indicates the area taken by the gas.

Applications of Level Indicator

Level indicators are used in various applications to determine fluid levels. The following are some of the applications.

- Gauging the levels in a drum or tank of oil or water.

- Sewerage pump control.

- Tower cooling water level control.

- Steam level monitoring.

- Early warning systems for tsunamis and sea levels.

- Batch processing and monitoring.

- Agricultural irrigation activities.

Advantages of Level Indicators

The advantages of level indicators include:

- Power Saver: Automatic level indicators are basic and don’t require much energy to function.

- Economic: Apart from consuming very little power, it’s relatively cheap to manufacture level indicators, and production does not require many materials.

- Automatic: Level indicators can function independently with minimum manual input. Due to electronic and digital components in the device, the level indicator can function on preset commands or remote control.

Drawbacks of Level Indicators

- The water level controls need to be changed after a while because time and continued exposure to humid conditions can wear them out.

- The rust and deterioration take effect as oxygen in the water reacts with the metallic components of the machine, reducing its life expectancy.

- The electronics used in level indicators are built separately and require extra encasing to avoid damage.

- Setup and installation of level indicators is complex and requires expert technicians.

Choosing the Correct Level Indicator Supplier

To ensure you have the most productive outcome when purchasing level indicators from a level indicator supplier, it is important to compare several companies using our directory of level indicator suppliers. Each level indicator supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each level indicator business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple level indicator companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services